| Customized clamps,Frames,Test fixtures,Test jigs |

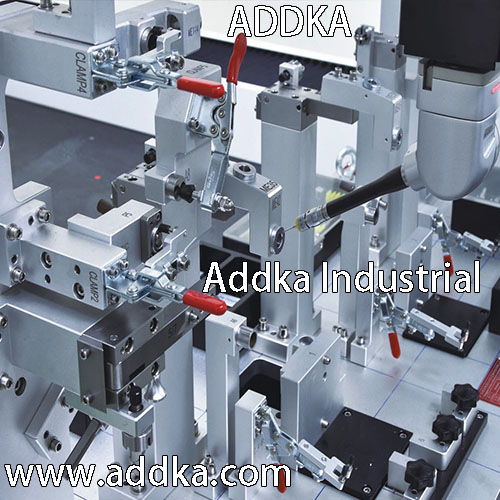

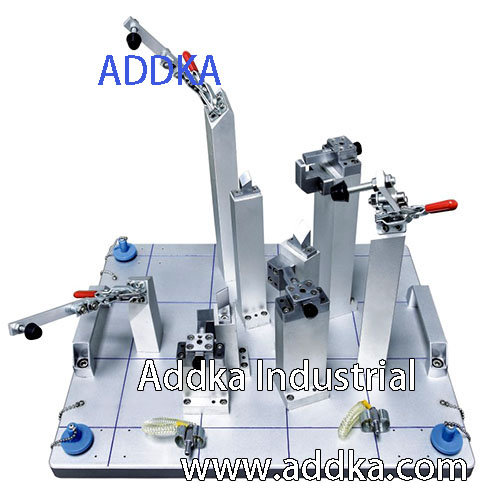

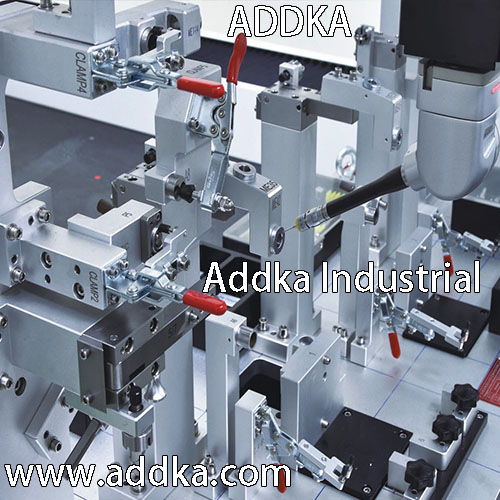

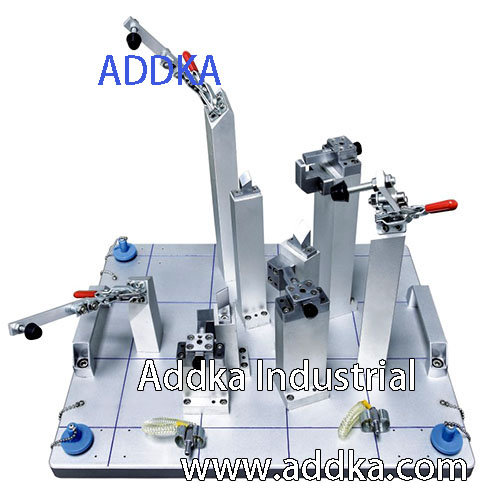

Horizontal Customized Installation Jigs and Fixtures

|

Customized Installation Jigs and Fixtures |

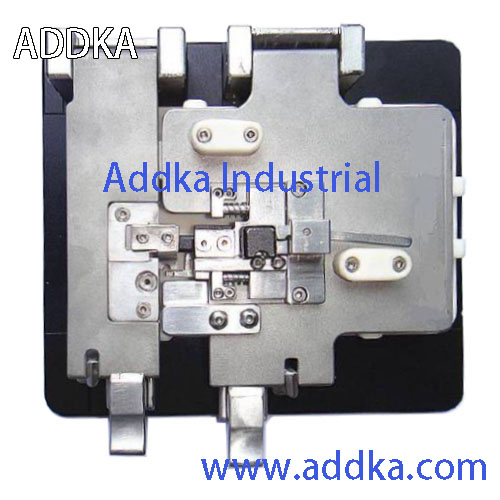

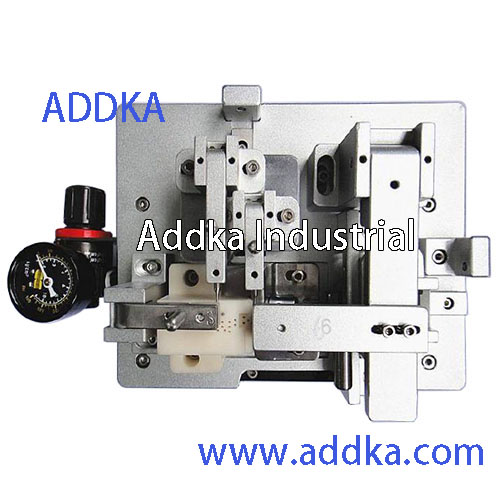

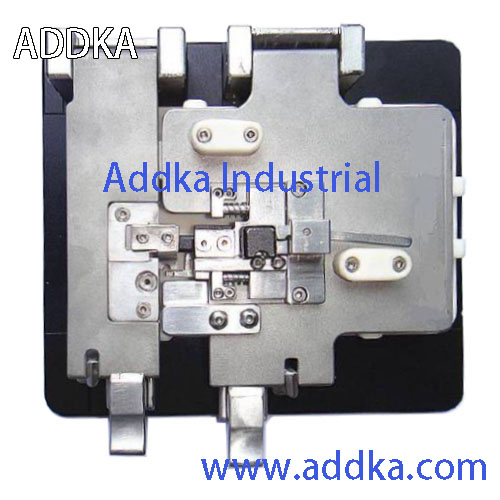

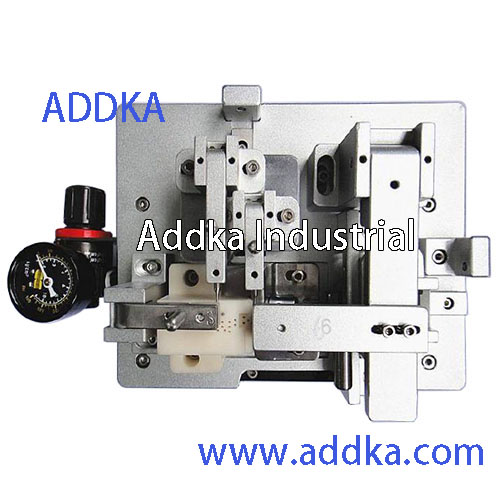

Short Test jig/Test fixture for PCB and PCBA

|

Electronic components Installation Jigs and Fixtures |

Alum,Copper Mobile phone camera assemble frame |

Multiple PCB test fixture,clamp,frame

|

Various tooling clamp fixtures Various tooling clamp fixtures |

Auto parts inspection fixture

|

Customized Installation Jigs and Fixtures Customized Installation Jigs and Fixtures

|

Auto parts inspection fixture,test jig

Test Fixture |

|

|

|

|

Test fixtures,Test jigs, Shieding Box,Antenna RF coupler

The test fixtures have been used for both engineering evaluation and production test.

PCB test jig,BGA test jig,LCD test jig,SMT test jig,ICT test jig,PCB test fixture,BGA test fixture,LCD test fixture,SMT test fixture,ICT test fixture

The testing jigs are used for:

Consumer Electronics: Video, Audio products, Bluetooth products,Auto products,Cafe Machine,LED Testingetc.

Industrial control: Motor Control Board, Equipment Board,Machine Board,etc.

Wireless industry: Smart Card Readers, NFC, WIFI, Wireless communication,Remote Control Testing,IoT Module Testing,etc.

Tele-communication: IP phones,Mobile Phone Testing,CDMA/GSM modules, VOIP,etc.

Medical: Electrocardiograph monitoring, Blood Press Meter, Stethoscope,etc.

Plastic/Metals: Metal Emblems, Stapler, Calculators, Screw Driver, Hammer,etc.

And many other OEM/ODM products... |

We can offer you the following services:

1 To map processing, according to your design drawings or videos to complete processing, and according to the need of assembling;

2 According to the specific requirements of the design, the first technical proposal ( including the specific structure, measuring principle, wiring methods ), to be customers to confirm the OK, we are responsible for processing, if necessary, can complete the connection all the work;

Analysis of 3 principle of products provide a full set of test technique, such as ICT testing tool, we provide professional technical services, from the structural design, processing, assembling, wiring, programming.

Finishes:

Anodizing, Electroplating, Polishing, Powder Coating, Blacken, Hardening, Painting and many other treatment of the parts.

Usually you can provide three kinds of information to us to make:

1)PCB files ( portel99, DXF, GERBER format can open ) if there is no figure file, need to provide space for copy PCB.

2)There are parts of the PCBA, front, side, bottom, mark the highest DIP part height.

3)Please use the drawing tool mark needle placement in the picture.

Some special circumstances need to provide in-kind, such as plastic parts positioning, shaped parts.

Fixtures to test medical hybrids, hybrids used for space satellites, multi-chip silicon-on-silicon modules, optical devices, cell phones, RF sub-assemblies, finger print detectors, guitar amplifiers, and many other applications.

For more products and more information,please don't hesitate to contact us. Thanks.

|

|

Various tooling clamp fixtures

Various tooling clamp fixtures

Customized Installation Jigs and Fixtures

Customized Installation Jigs and Fixtures